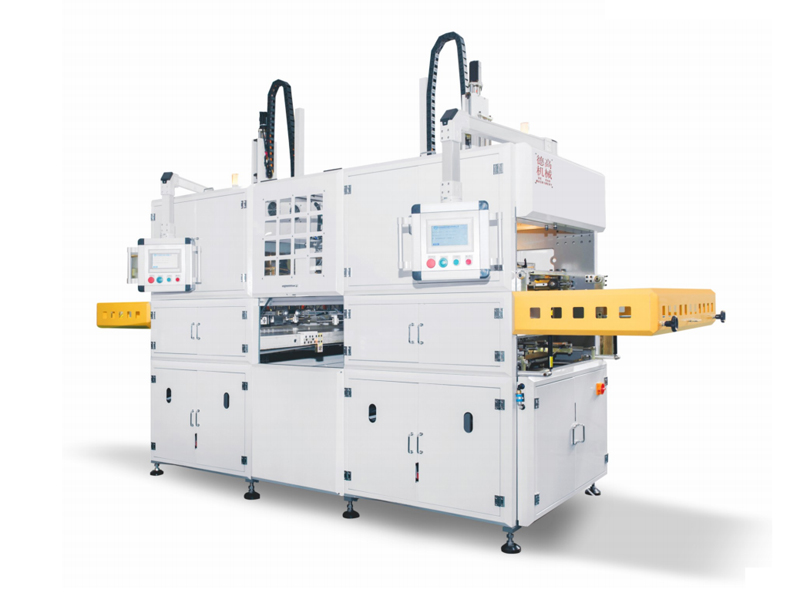

功能特點

該機與自動定位機自動聯機後,即為全自(zì)動製盒機。亦可自動(dòng)聯機兩台,即為全自動雙頭製盒機。凸輪傳動、自動調模、免換(huàn)鏟刀、免換壓泡板等。集智能、科學、效率的設(shè)計理念為一體。

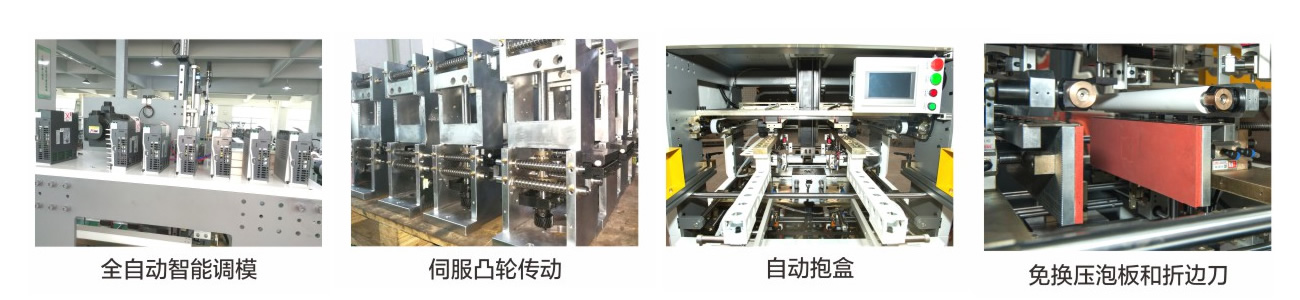

1.伺服凸輪傳動:采用伺服馬達通過行星減速機(jī)驅動凸輪動作,元成紙(zhǐ)盒的包邊折(shé)入成型(xíng)工作,運(yùn)行穩定,使用壽(shòu)命長(zhǎng)

2.自動調模:輸入紙盒的長(zhǎng)寬高和模具的高度後,機器會自動調整好相(xiàng)關成型位(wèi)置,生產時即自動鎖(suǒ)固,無(wú)需人工調整和鎖固,操作簡(jiǎn)單,易學易懂。

3.免換壓泡板和折邊(biān)刀:該機已(yǐ)經裝好固定(dìng)長度的壓泡板和折邊刀,適應任意尺寸紙盒的生產,無需更換拆卸,節省了轉板時間和成本。

4.自(zì)動(dòng)抱盒:與自動定位機組合後,可自動將定位好的紙盒抱入(rù)機器成型,待(dài)包邊(biān)、折入(rù)、壓泡完成(chéng)後自動抱出,無需人工(gōng)參與,保障安全,穩定快捷。

5.存儲記憶功能:隻要是生產過的紙(zhǐ)盒,都(dōu)會無限數(shù)量(liàng)的自動(dòng)保存該數據,再次生產(chǎn)該紙盒(hé)時,調出確認即可,無需再次調整,真正的實現人(rén)工智(zhì)能(néng)化。

6.多(duō)次壓泡:單邊400公斤的壓(yā)力,可實現前後左右分別或整體的12次壓泡,盒體平整美觀無(wú)氣泡。

Functional features

After the machine is automatically connected with the automatic positioning machine, it is a fully automatic box making machine. Two automatic double head box making machines can also be connected automatically. Cam drive, automatic mold adjustment, no blade change, no first pressure foam board, etc. Set intelligent, scientific, efficient design concept as one.

1. Servo cam drive: the servo motor is used to drive the cam action through the planetary reducer, so that the edge of the paper box can be folded into the forming work, with stable operation and long service life

2. Automatic mold adjustment: after inputting the length, width and height of the carton and the height of the mold, the machine will automatically adjust the relevant molding position, and lock it automatically during production, without manual adjustment and locking, which is easy to operate and understand.

3. No change of pressure foam board and edge folding knife: the machine has been installed with fixed length pressure foam board and edge folding knife, which can adapt to the production of carton of any size without replacement and disassembly, thus saving the time and cost of plate rotation.

4. Automatic box holding: after combined with the automatic positioning machine, it can automatically hold the positioned box into the machine for forming, and automatically hold out after the completion of edge wrapping, folding and bubble pressing, without manual participation, ensuring safety, stability and rapidity.

5. Storage and memory function: as long as the carton is produced, it will automatically save the data in unlimited quantity. When the carton is produced again, it can be called out for confirmation without further adjustment, which truly realizes artificial intelligence.

6. Multiple bubble pressing: the pressure of 400kg on one side can realize 12 bubble pressing on the front, back, left and right sides respectively or as a whole. The box is flat and beautiful without bubbles.

微信公(gōng)眾號

微信公(gōng)眾號 微信小程(chéng)序

微信小程(chéng)序

微信公(gōng)眾號

微信公(gōng)眾號 微信小程(chéng)序

微信小程(chéng)序

手機網(wǎng)站

手機網(wǎng)站