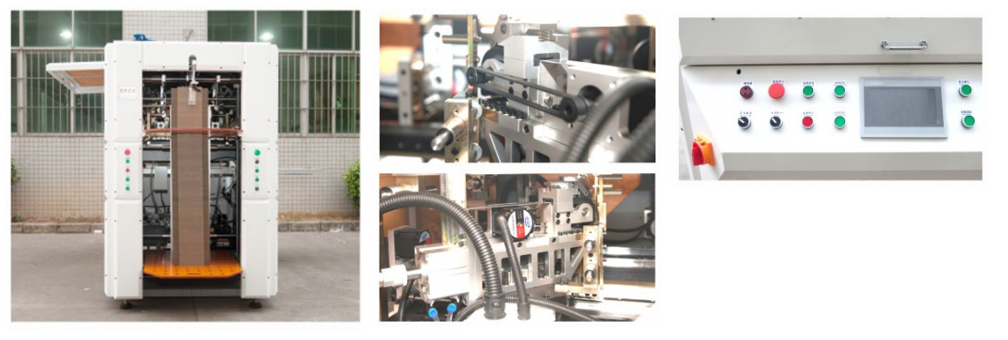

功能特點

1.智能調模(mó):輸入紙盒尺寸後機器會自動調節並鎖固,無需糾正,啟動生(shēng)產即(jí)可。

2.飛達送(sòng)紙:新款飛達送紙,適應薄、厚、彎,開槽、瓦楞等材料的四角貼角。

3.連續送料:雙紙台裝置,紙(zhǐ)堆高度1.2米,循(xún)環(huán)使(shǐ)用,提(tí)高效率,降低勞動強度。

4.拉盒(hé)功能:機械式下拉盒結構,平穩快速,適合(hé)匹配各種定位(wèi)線的(de)聯機聯線。

5.防堵帶槽:高精度、不變形鍍特氟龍膠(jiāo)帶槽,完全避免堵帶、粘帶的問題。

6.整體機架(jià):大型加工(gōng)中心製作的整板機架,保(bǎo)障各部件的平行與垂(chuí)直, 裝配精度等。

7.品牌電器:采用鬆下、台達、施耐德等電器,通過PLC和(hé)伺服馬達完(wán)成運控,觸摸屏操作,安全、簡單、人機合一。

Functional features

1. lellient mold adjustment: the machine will automalially debug and ock ater iputting the box sizelt can start the produdion without corredion and psilioning.

2. Feida paper feeding new Feida paper feeding suitable for thin, thick, curved, grooving, comugatedand other malerials.

3. Continuous feding double paper platform device, it can stack up to 1.2m in height, recycing, improving eficiency and reduding labor intensity

4. Puling box function: mechanica puling box structure. stable and fast, suitable for conneding vanous posttoning ines.

5. Anl-blocking groove: high precision,nondefomation Tefion tape groove. completely avoid the problem oftape bocking and ape pasting.

6 Whole frame: the whole frame made by large machine centre ensures the paralle ism and perpend cularty of al parts high assembly procsion.

7. Htghqualty ectical aplances Panasonic Detta Schneider and other elcrica pplance. crntoldby PLC and seno molor, touch scree operatioi sale, smple, man-machine ntgabion.

微信公眾號

微信公眾號 微信小程序

微信小程序

微信公眾號

微信公眾號 微信小程序

微信小程序

手機(jī)網站

手機(jī)網站